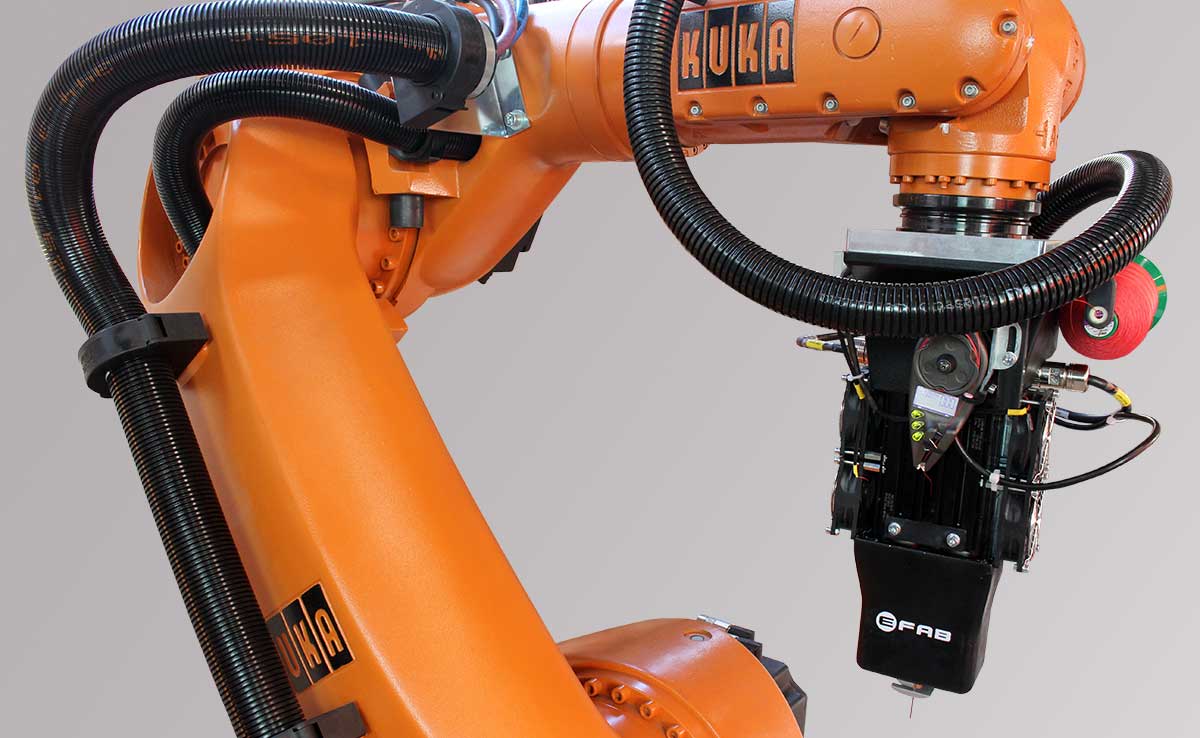

eCTH (Composites Tufting Head) is specially designed for production of sub-preforms and preforms.

It is an unique device for high speed tufting on carbon or glass composites typically used in the field of aerospace, automotive, wind energy or industrial lightweight construction.

High Speed Tufting

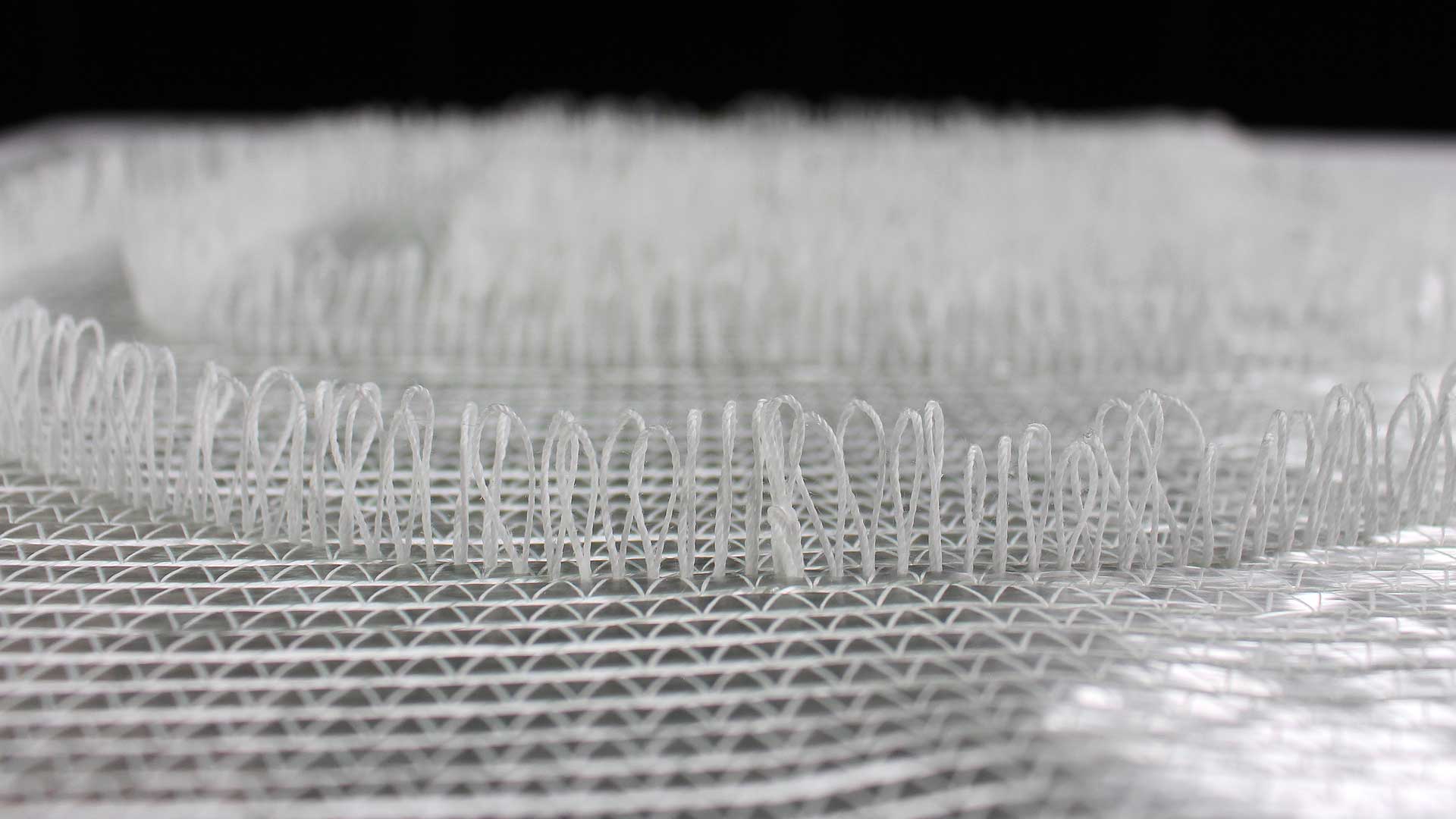

This high speed tufting head is working with one needle and single thread. It is inserting a thread through a layered composite fabrics, using a single needle that, after insertion, moves back along the same trajectory leaving a loop of the thread inside or outside of the structure, whether it is a glass or carbon fibers composites.

It resembles stitching, but it is different. eCTH tufting head only requires access from one side of the preform.

Uniform Tufting

Thanks to unique tufting technique, it forms very uniform and even loops. All tufting parameters (stitch rate, stitch length and profile of needle movement) are electronically adjustable and there is no need for any mechanical adjustments.

Tufting is considered a more economical and flexible method compared to 3D weaving or 3D braiding to include z-fibres in laminated composites. Depending on the equipment used, all shapes and forms may potentially be reinforced by eCTH tufting head.

Features and Specification

|

High Speed Tufting (up to 1,000 stitches/min) |

|

Stitch length: 3 – 30 mm |

|

Variable stitch length |

|

Open thread loop (lower side seam) |

|

Uniform tufting |

|

All tufting parameters (stitch rate, stitch length and profile of movement) are electronically adjustable |

|

No need for any mechanical adjustment |

|

By using tool changer, various end effectors can be changed easily and quickly. |